Automatic electric alternator motor fan motor stator coil forming machines for induction motor manufacturing

(1) Main feature and introduction

This motor stator coil forming machine is consisted of upper mould, lower mould, protective teeth, machine framework and electrical cabinet.

The Middle forming machine main is powered by hydraulic system and controlled by PLC.

Its inward expand and outward movable station is much convenient for big rotor stator.

The stator coil forming is done by inner expansion, outer wrapping and overhanging pressing.

This coil forming machine has advantages of mature and advanced technology, reliable quality, easy operation and maintenance.

Production capacity ≤14s/set (exclude loading/unloading time)

Primary qualification rate ≥98.5%, after rework, the rate ≥99.5%

This machine adopts safety grating protection system.

Operator need to stand when operating.

(2) Application

This motor stator coil forming machine is appropriate for micro induction motor like alternator motor, air conditioner motor, compressor motor, fan motor, washer motor, pump motor etc.

(3) Technical data

| Product name: |

Automatic fan motor / alternator motor stator coil forming machine |

| Stator ID |

Φ20~Φ100 mm |

| Stator OD |

≤Φ160 mm |

| Stack height |

≤190 mm |

| Displacement of cylinder |

20 L |

| Power |

380V/50Hz |

| Dimension |

(L)1200×(W)800×(H)2300 mm |

| Weight( tooling included) |

800 kg

|

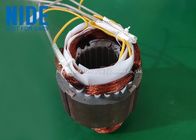

(4) Picture show

(5) Machine operation steps

1. After connected to the power source and air source, switch the button to on.

2.Press hydraulic start button; switch to auto mode.

3. Put stator into the tooling. Press “Start” button by two hands. Machine will auto form.

(6)The motor stator coil forming machine video:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!