automatic double stations coil winding machine for multi-pole BLDC motor stator

1.Product overview:

The motor stator coil winding machine is mainly used for multi-pole BLDC motor stator winding,adopt needle winding technology. Each action cycle will wrap 2 stators, greatly improve the production efficiency, manual feeding, automatic clamping die, reduce labor intensity;Multiple tap (screen setting), wire clamping and wire cutting can be realized during winding process.The number of slots and cycles can be set by man-machine interface; all aluminum alloy (anodizing treatment) plus imported acrylic protection;Electric by PLC, display, servo motor control, set, display safe and reliable.

2.Function and Characteristics:

1,For multi-pole stator winding, manual loading and unloading, automatic clamping, winding and shearing;

2,Frame adopts National Standard 4040 aluminum profile, table boardadoptsQ235.

3,Tooling and fixture parts adopt downward positioning mode, stable positioning and reliable tightening.

4,Wire clamping and wire cutting, line part structure compact, wire clamping and wire cutting is completed at one time;

5,Different stator and winding parameters can be quickly switched through the HMI to adapt to different stator requirements.

6,Quick change-over of tooling;(20 minutes with proficiency)

7,Full aluminum alloy protection

8,PLC control, fault display

3.Specification:

| Product name: |

Double stations BDLC motor stator needle coil winding machine |

| Wire diameter: |

φ0.13—φ1.2mm(Other specifications can be specially designed) |

| Applicable pole number: |

multipolar |

| Stator ID: |

φ25—φ60mm (Other specifications can be specially designed) |

| Stator OD: |

φ60—φ200 mm (Other specifications can be specially designed) |

| Stack length: |

10-80mm(Standard stroke) |

| Servo mechanism: |

One Indexing Motor , One Winding Motor with Brake, two wiring motor |

| Spindle speeds: |

0-260 RPM adjustable |

| Air pressure: |

0.5-1MPa |

| Power: |

10KW |

| Voltage: |

380V/50HZ Three phase four wires |

| Dimension: |

1100*1300*1700mm(Length * width * height) |

| Weight: |

500KG |

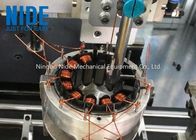

4.Picture show:

1.The BLDC motor stator needle winding machine adopts needle winding techonlogy

2.The motor stator needle winding machine has two coil winding working stations,greatly improve production efficiency

3.The BLDC motor stator after coil winding

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!