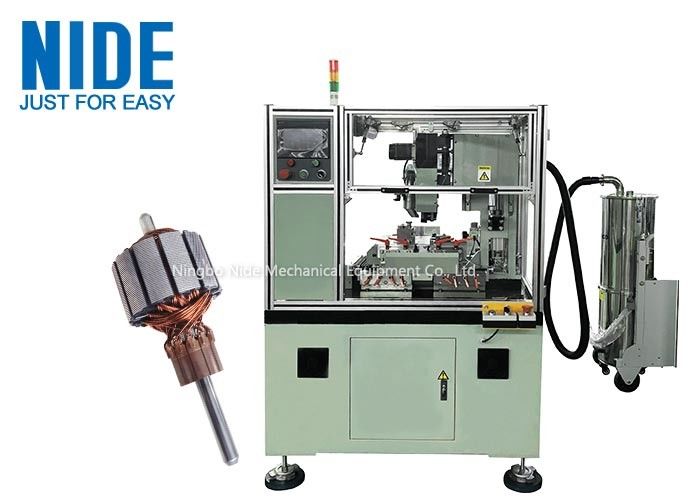

Automatic armature commutator turning and cutting machine for Electric Universal and DC motor

1,Introduction

This automatic armature commutator turning lathe machine is used for electric motor armature commutator surface cutting and turning. Equipped 1set servo motor drive 1pc diamond cutter, 1set servo motor driving belt drive armature rotation, cutter cutting commutator. Color LCD displayer, production parameter could be edit, modified, stored and encrypted, etc. total 100pcs armature’s production parameter could be stored. During whole action, parameter could be display, and machine has automatic alarm function once abnormal condition occurring.

2,Application:

The armature commutator turning machine is suitable for DC motor armature and Series excited motor armature.

DC motor armature: automobile motor armature, motorcycle starter armature, etc.

Series excited motor armature:home appliances armature, power tool armature, vacuum cleaner armature, mixer armature, etc.

3.Main technical data:

| Commutator roundness: |

0.0025-0.0035mm(depends on user's commutator material, armature shaft quality and bearing position quality) |

| Roundness between bars |

≤0.0015-0.0025mm |

| Surface Roughness: |

≤Ra 0.4(depends on customer's armature quality) |

| Armature OD: |

Ф20~Ф82mm |

| Shaft length: |

32~250mm |

| Shaft OD: |

Ф3~Ф16mm |

| Commutator OD: |

Ф8~Ф40mm |

| Max. cutting volume: |

first cut—rough cutting Max 0.20mm(in diameter direction of commutator) |

| Speed regulation range: |

0~60Hz |

| Control: |

PLC system |

| Cutting speed : |

PLC adjustable |

| Z direction cutter feeding speed: |

settable on touch screen, stepless adjustable |

| Z direction cutter returning speed: |

set on program |

| X direction cutter feeding speed: |

settable on touch screen, stepless adjustable |

| X direction cutter returning speed: |

set on program |

| Z direction cutting length: |

settable on touch screen, Max. could set 4times different cutting length(Max 30mm) |

| Z direction travelling: |

Max 50mm |

| Production efficiency: |

whole cycle≤12sec/pc(twice cutting) |

| Air pressure: |

4~6kg/cm2 |

| Fixture: |

Diamond V block |

| Total power: |

2.2KW |

| Machine power: |

50/60Hz AC220V±10%(single phase) |

| Burring removing machine power: |

50/60Hz AC220V±10%(single phase) |

| Vacuum cleaner power: |

50/60Hz AC380V±10%(three phase) |

| Weight: |

about 1,100Kg |

| Machine dimension: |

1,100mm x 1100 mm x 1,830mm |

4,Features:

1) Suitable for 3shifs continuous production, manually loading and unloading. Production efficiency is: about 1800~2200pcs / shift

2) Production sequence: manual loading→ auto cutting, and auto removing burs → manual unloading

3) Cutter could do Max. 4 times and Min. once cutting, the cutting parameter for each time is settable, including cutting volume, cutter moving speed, belt speed, etc.

4) Two operation mode: automatic and manual

5) Could store cutting parameter for total 100nos armatures

6) Cutting limitation to remind operator to change cutter timely

7) Display parameter, including shift output, total output, consuming time, etc. Auto alarm once abnormal condition occurring.

5,Picture show:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!