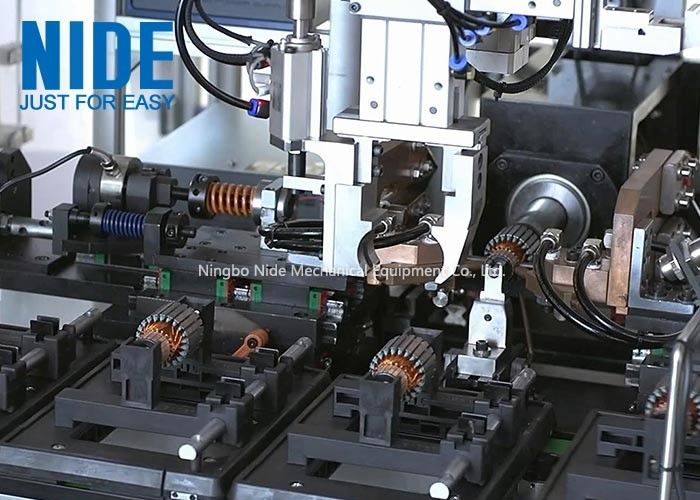

Automatic Power Tool Motor Armature Winding Machine Rotor Assembly Line

Quick Detail:

1. This armature assembly line is of high automation. Operater only needs to loading and unloading.

2. The working effiecency is high, and it saves labor cost.

3. It can be customized.

4. The armature assembly line can detect the unquanlified rotor.

Description:

Nide produces a full range of rotor production machine. It can be customized as per different requirement. This rotor assembly line consistes of armature winding and fusing machine, armature wedge inserting machine, commutator turning machine, rotor balancing machine and armature testing machine.

Process:

armature winding and fusing—--wedge inserting—commutator turning-----armautre balancing-----armature testing.

armature production machine.pdf

Armature winding and fusing machine

This machine can do coil winding and fusing in one machine. It saves cost and space. It has two station, one for winding, the other for fusing. After the winding, mechanical arm will transfer it to the fusing station. And carry a unwound rotor to the winding station.

Wedge inserting machine

The wedge material can be as per customer's requirement, DMD, DM, polyester film are all can be used in this machine. he machine will finish the work such as the rotor lifting, clamping, shaping of the insulating paper, cutting and inserting automatically.

Commutator welding machine

This machine is applied to DC motor and universal motor. It is controlled by PCL, all the data setting can be done on the touch sreeen. There are four power control method, namely secondary constant current, secondary constant voltage secondary constant frequency.

Commutator turning machine

Equipped with lubrication device and aluminum alloy frame, this machine features advance technology and modern shape, has easy operation system and self-checking system. The cutting deminsion can be set in the touch screen.

Rotor testing machine

It can be used to test rotor performance and commutator roundness. If it is unquanlified, machine will detect it. The mechanical arm will pick it out to waste position.

Click below picutre to view the vidio.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!