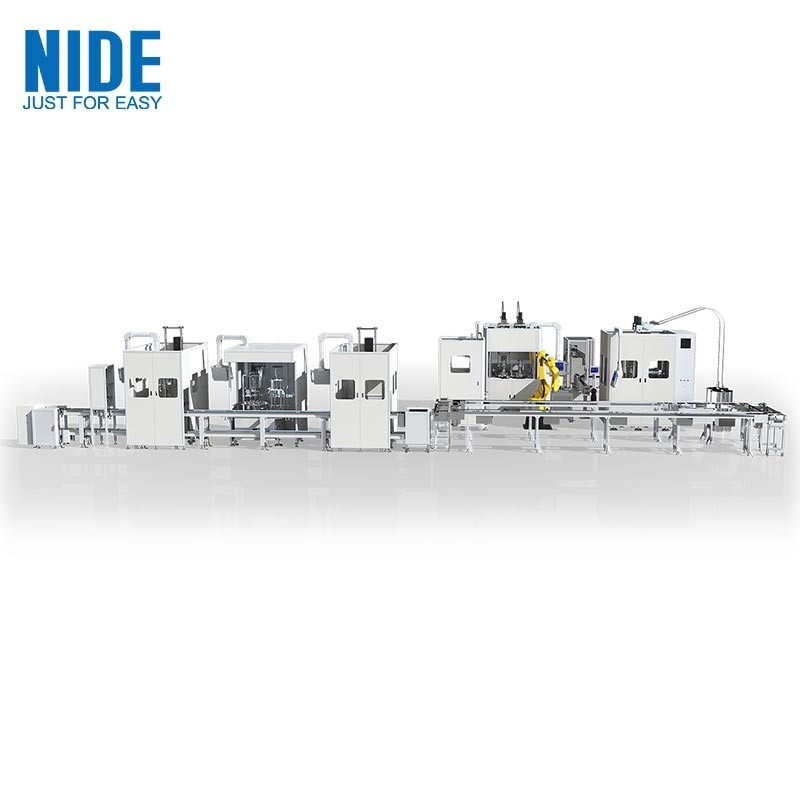

Full Automatic Three-phase Stator Production Line

All equipment of the whole stator production line features the automatic functions of feeding, paper insertion, coil insertion, lacing and forming through a high degree of integration. The machine has the functions of automatic stacking, automatic phase paper insertion, automatic feeding, automatic detection, complete line data display, remote control, etc.

This stator product line has a large number of successful cases, improves the competitiveness for motor manufacturers with lower labor costs and high productivity.

Without impact to production capacity, this production line with much less workers than other machines.

Stator Production Line Basic Specification

| Product name: |

3 phase stator production line |

| Stator O.D.: |

Φ80-Φ135 |

| Stator I.D.: |

Φ50-Φ100 |

| Stator Stack Length: |

30-120mm |

| Wire Size: |

0.3-1.2mm |

| Filling rate: |

≤80%;it will be determined by wire and slot sizes |

| Size: |

16000*8500 |

Stator Production Line Production Process

Stator loading, laser marking and insulation inserting→ winding for primary and secondary → Pre-forming → Wire connecting, welding and phase paper inserting→ Middle forming→ Lacing→ Final forming→ Slot wedge expanding→ Appearance and electric inspection

Stator Production Line Technical Proposal

Cycle time: ≤30 sec/pc

Equipped with MES to realize production process traceability and electric boards for whole production lines and equipped working stations.

100% for reliability of testing system and online inspection rate for key parameter

Stator Production Line Machine Features

– Machine dimensions:73000*6200*6300

– Coating method:Slit extrusion coating

– Coated film width tolerance:±0.3mm

– Target substrate width:Max.1400mm

– Drying method:Steam, heat-transfer oil or electric heating

– Coated film front and back tolerance:±0.4mm

– Coating speed:Max.100m/min

– Coated film weight tolerance:±1.5%

– Winding alignment:±2mm

With good service, unique philosophy, professional team and reliable quality, we win the worldwide customers' confidence gradually. We directly and indirectly supply our products to more than 50 countries. Among the customers, many of them are the world-renown companies.

| Customerized service |

1. Customized product design and manufacturing |

| 2. Customized tranning |

| 3.Technical suggestions |

| After-sales service |

1. Warranty Period: 12 month usually |

| 2. Overseas service center available |

| 3. Engineers available to service overseas |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!